Cast in place concrete also known as poured in place is a concreting technique which is undertaken in situ or in the concrete component s finished position.

In situ concrete wall thickness.

This method statement for in situ concrete general concrete work describes the process to be implemented during the entire activity for such as in situ concrete concrete foundations slab on grade blindings columns beams retaining walls slabs raft concrete precast concrete self consolidating concrete mass concrete and any structural concrete works.

Remove all loose and spalled concrete by means of wire brush or an orbital sanding machine the vertical faces of the liner shall be abraded to a height of 150mm for in situ lining overlap.

Reinforced concrete construction typically consisted of 4 or 6 100 mm or 150 mm thick cast in situ concrete external walls that were full height to the parapet and continuous with the foundations figure 1.

In situ precast and tilt up concrete walls concrete can be cast in situ or precast between vertical formwork to produce walls that carry vertical and or horizontal loads in structures.

Unless such walls are of massive proportions the concrete will usually be designed and reinforced with steel rebars in accordance with eurocode 2 part 1.

Cast in place concrete is the preferred choice for concrete slabs and foundations as well as components such as beams columns walls roofs and so on.

Showing 1 11 of 11 show more results per page refine search results.

Concrete wall construction process 1.

Smith in marine concrete structures 2016.

It has many advantages over the cast in situ concrete method for construction.

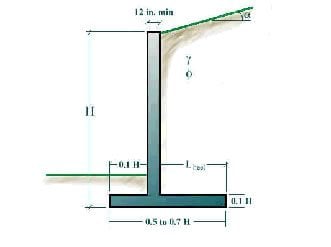

In situ reinforced concrete wall structure system 11 an in situ reinforced concrete wall structure system typically comprises of items such as permanent formwork concrete and reinforcement.

Precast concrete is the new construction technic that makes construction speedy and economical on the large construction projects.

The thickness of reinforced concrete walls is affected by the fire rating of the structure to which they are to form a part.

The concrete should be fully cured and should have a moisture content of less than 5.

Axis distance is measured from the surface of the concrete to the centreline of the main reinforcing bars.

Steel bars are placed horizontally and vertically in the wall in a grid.

Cast in situ concrete diaphragm walls have also been used to create permanent sheet pile quay walls.

Concrete building construction concrete construction can be identified by thick walls and deep window and door reveals.

However care must be taken with the construction to ensure the quality of the wall trench cutting equipment with hydraulically driven rotary cutters is preferred to the traditional hydraulic grabs as a better quality is.

Cast in situ concrete is the easy and conventional method that we have been seeing for past decades.

Generally if wall thickness is smaller than 100 mm then reinforcement bars are installed in one layer.