The parts are then cooled below the solidification temperature to form a permanent electro mechanical bond.

Hot bar reflow soldering process.

The base substrate is located in a fixture and flux is applied to the pads.

A process start signal is given to the soldering control unit.

Hot bar reflow soldering bonding fundamentals technical articles and whitepapers blogs videos training information and more.

Pulsed heated soldering differs from traditional soldering because the reflow of solder is accomplished using a heating element called a thermode which is heated and cooled down for each connection.

Pressure is applied during the entire cycle including heating reflow and cooling.

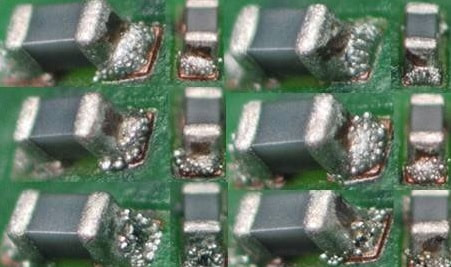

3 layouts for hot bar reflow soldering.

Reflow soldering process overview.

Hot bar reflow soldering is a selective soldering process where two pre fluxed solder coated parts are heated using a heating element called a thermode or a hot bar to a sufficient temperature to melt the solder.